Pressure Seal Gate, Globe & Check

DSI® Pressure Seal valves are designed for high pressure, high temperature applications such as Steam-Generation Stations, Industrial/Chemical Processing Plants, Thermal Power Generating Plants and other processing facilities throughout the world. Pressure Seal valves are engineered and manufactured in strict conformance to ASME, ANSI, ASTM, API and other applicable standards. The DSI Pressure Seal product line offers flex-wedge and parallel slide gate valves, straight and Y-pattern globe valves, swing, lift and tiltdisk check valves.

Pressure Seal Design

The segmental thrust ring absorbs all the thrust applied by internal pressure. A hardened Stainless Steel protective ring prevents deformation of the top surface of the soft steel, 304 Stainless or 316 Stainless with a high density graphite gasket. The gasket can be removed freely without damaging the sealing surface of the body.

General Design Specifications

DSI Pressure Seal Valves are manufactured in strict accordance with the following standards:

- ASME B16.34

- ASME B16.10

- ASME B16.25

- API 598

Full Line of Pressure Seal Valves

- Gate

- Globe

- Check

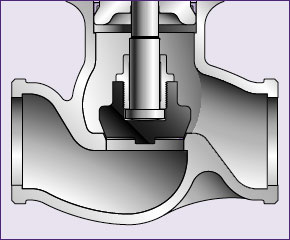

Pressure Seal Gate Valves

DSI® offers a broad range of Cast Steel Pressure Seal Gate valves in Buttweld and Flanged end connections.

- Size Range: 2″ thru 24″

- Pressure Class: 600-4500

- Style: Flexible Wedge and Parallel Slide design

- Materials: A216 WCB, WC6, WC9, C5, C12, C12A, CF8M and special alloys

Standard Construction Features

Flexible Wedge Sealing Design

The flexible wedge is a one-piece, fully guided cast wedge with a central hub to allow the seating faces to move relative to each other, thus compensating for distortion of the body seats due to thermal expansion or piping loads. Seat ring and wedge seating face are set at a 9° angle from vertical to minimize sliding contact of the wedge and seat ring during opening and closing.

Wedging actions help effect a tight seal in low differential pressure services. Flexible wedge construction resists wedge sticking or binding in services where the valve may be closed when cold and opened when hot. Seating surfaces are hardfaced with Stellite®6 to provide high life cycle capability in very high differential pressure services

Parallel Slide Design

The gate is a split design using two discs spring loaded and held together by a gate holder with a corrosion reservior spring to provide initial energizing when closed. The gate relies for seat tightness on the primary fluid pressure acting on the downstream seat. There is no wedging action or extra loading on the seats resulting in considerably lower operating torque. During closing there is a bevel on the bottom of the gate to guide it in between the seats and recompress the spring. Seating surfaces are hardfaced with Stellite®6 to provide high cycle capability in very high differential pressure services.

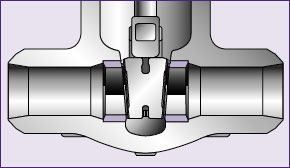

Pressure Seal Globe Valves

DSI® offers a broad range of Cast Steel Pressure Seal Globe valves in Buttweld and Flanged end connections.

- Size Range: 2″ thru 24″

- Pressure Class: 600-4500

- Style: Straight Pattern, Y-Pattern and Non-Return (Stop Check) design

- Materials: A216 WCB, WC6, WC9, C5, C12, C12A, CF8M and special alloys

Standard Construction Features

Straight and Y-Pattern Seating Design

- All DSI globe valves utilize a seating design that consist of a guided disc which seals fully with the seat to provide a tight seal. Seating surfaces are hardfaced with Stellite®6 to increase the life cycle.

- All DSI globe valves are unidirectional.

Pressure Seal Check Valves

DSI® offers a broad range of Cast Steel Pressure Seal Check valves in Buttweld and Flanged end connections.

- Size Range: 2″ thru 24″

- Pressure Class: 600-4500

- Style: Swing Check design, Straight Lift Tilt Disc design, and Y-Pattern design

- Materials: A216 WCB, WC6, WC9, C5, C12, C12A, CF8M and special alloys

Standard Construction Features

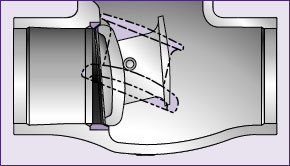

Swing Check and Tilt Disc

Pressure Seal check valves are designed for reliability in high velocity service applications to prevent backflow. The check valves are designed to operate in either vertical upflow or horizontal pipe runs. Seating surfaces are hardfaced with Stellite®6 to provide high life cycle capability.

The swing check design offers a higher flow coefficient than a tilting disc design with higher flow area. The tilting disc is a non-slam design.