Cast Steel Gate, Globe & Check

For years, DSI® Cast Steel Valves have been satisfying the needs of Petroleum Refineries, Chemical Processing Plants, Power Generating Plants, and and other processing facilities throughout the world. Our Cast Steel Valves are designed, engineered and manufactured in strict conformance to API, ASTM, ASME, ANSI and other recognized standards. DSI® Cast Steel Valves are not only characterized by outstanding performance, reliability and quality, they’re also known for their standard features normally optional in other brands. All flanged DSI® Cast Steel Valves come standard with 125-250 RA flange finishes. DSI® utilizes flexible graphite packing, a variety of gasket materials and exacting assembly and testing procedures to ensure compliance with the World’s emissions control standards.

Cast Stainless and High Alloy Valves

Gate Valves

- Size Range 2” to 24”

- Pressure Class 150# to 1500#

- API 603 / ASME B16.34 or API 600

- NACE Certification Available

- Low Fugitive Emission Compliant

Globe Valves

- Size Range 2” to 12”

- Pressure Class 150# to 1500#

- ASME B16.34 or BS 1873

- NACE Certification available

- Low Fugitive Emission Compliant

Check Valves

- Size Range 2” to 24”

- Pressure Class 150# to 1500#

- ASME B16.34 or API594

- NACE Certification Available4

Cast Carbon, Chrome and Low Temperature Globe Valves

Gate Valves

- Size Range 2” to 56”

- Pressure Class 150# to 2500#

- API 600 / ASME B16.34

- NACE Certification Available

- Low Fugitive Emission Compliant

Globe Valves

- Size Range 2” to 14”

- Pressure Class 150# to 2500#

- ASME B16.34/BS 1873 (API 600 Design)

- NACE Certification Available

- Low Fugitive Emission Compliant

Check Valves

- Size Range 2” to 36”

- Pressure Class 150# to 2500#

- ASME B16.34 / API 594

- NACE Certification Available

- Low Fugitive Emission Compliant

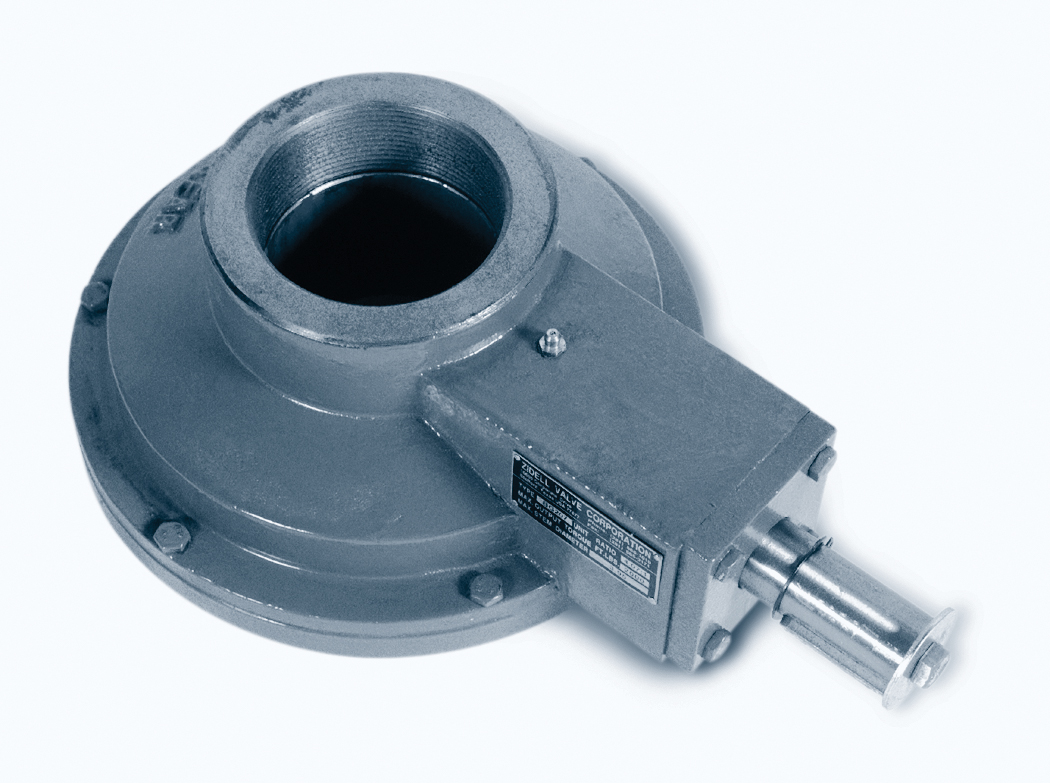

Bevel Gear Operators

Zy-Gear gear operators are designed for long lasting dependable service in oil & gas and industrial actuation applications. For years project managers and engineers have specified and relied upon Zy-Gear and other quality DSI products for petroleum refining, chemical processing, power generating, pulp and paper, water treatment and other processing facilities located throughout the world.

The Zy-Gear product line offers a worm or bevel gear model for applications where dependable, accurate actuation is required. The Zy-Gear product offering has been computer designed, manufactured and tested to provide smooth, dependable gear operation for many years.

All Zy-Gear gear operators conform to all applicable recognized standards and can be custom designed to meet your project requirements. Specify Zy-Gear gear operators for all your actuation applications and you’ll experience first hand what DSI dependability really means.

Zy-gear bevel gear operators actuate your multi-turn valves. Zy-gear bevel gears are constructed with all the materials, design, technology and engineering you expect to find in a quality gear.

Standard Features

- O-ring sealed and lubricated for life.

- Totally enclosed for buried service, high temperature, low temperature, numerous chemical plant conditions and full weather resistance.

- Comprehensive product line for torque capability.

- Machine-generated gearing assures minimum backlash and smooth operation.

- Sturdy materials, proven design and quality manufacturing ensure trouble-free life.

- Bevel pinion and bevel gear supported by anti-friction ball bearings.

- Stem protector is available in standard NPT pipe sizes

- High strength carbon steel handwheel included

- Standard NPT stem protector thread

Product Groups

- BG107

- BG207

- BG307

Available Literature

Cast Stainless and High Alloy Cryogenic Valves

Applications such as liquefied natural gas, and other low temperature fluids, present special valve functionality challenges caused by extreme low temperature conditions. DSI® gate, globe and check valves for cryogenic services, are specially prepared and designed to overcome these challenges.

Appropriate component materials are utilized for body and trim, offering superior impact strength, excellent corrosion resistance and heat loss properties. An extended bonnet and gas column design is also normally employed to provide thermal insulation at the stem seal and stem packing area. At sufficient length, this design feature places the functionality of the stem seal in the vapor zone of the liquid media providing safe and continuous valve operation.

A variety of body, trim, seat and seal materials are available for use in cryogenic service. Customer specified options, such as body cavity vent hole, special extension lengths and Kel-F materials, are also available upon request.