High-Quality Oil Desalter With Edge Design

Design and Build Quality of Edge Oil Desalters

In time, we’ve managed to perfect the design and build quality of our oil desalters. In fact, our modern designs can support several distributions of electrode locations. What’s more is that you can adjust these locations to predefined operational requirements and processing needs. FET, i.e., leading crude oil desalter manufacturers, offers the first Edge design, Edge II, and Edge III. We also offer NU-STATIC, which works as a distillate treater or coalescer.

Benefits of Using Edge Desalters

- Reduced salt carryover for minimized corrosion, chemical costs, equipment fouling/foaming, maintenance costs and unplanned shutdowns

- Decreased water carryover for lower energy costs, stabilized unit operations, increased crude throughput, minimized slop oil production and reduced waste water treatment costs

- Reduced power consumption and chemistry optimization

- Solid-steel rod electrodes unaffected by high oxygen concentrations (typical life of +20 years)

- Insulators (grid hangers) with proprietary materials, ensuring highest tensile strength in the industry

- Optional severe service entrance bushing for higher pressure/temperature operation

- Compatible with the ForuMIX™ high-efficiency multiphase mixer

- In accordance with industry standards and best practices (ISO certified)

- Extensive user list with installations around the world

- Pilot plant services

Applications of Edge Desalter Series

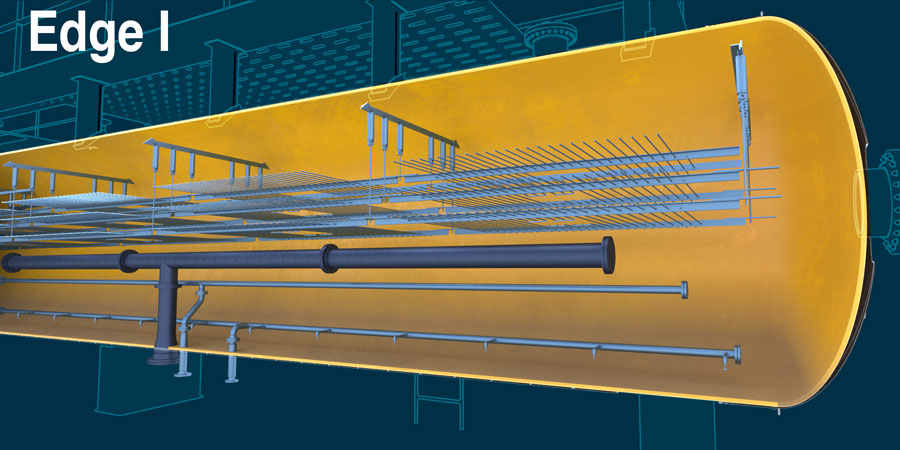

Original EDGE

Original Edge offers applications for lighter crudes, crudes in high-water content, and crudes for production-based applications.

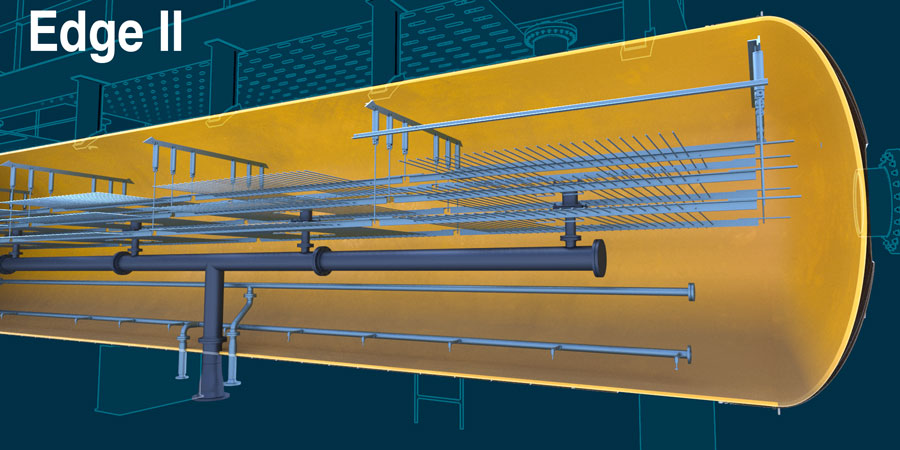

EDGE II

Edge II supports crude oil that has a high volume of solid content. Edge II offers added flexibility when it comes to changing feedstocks and higher throughput rates across all existing vessels. It also works with crude oil that has high solids content as well as emulsion feedstocks.

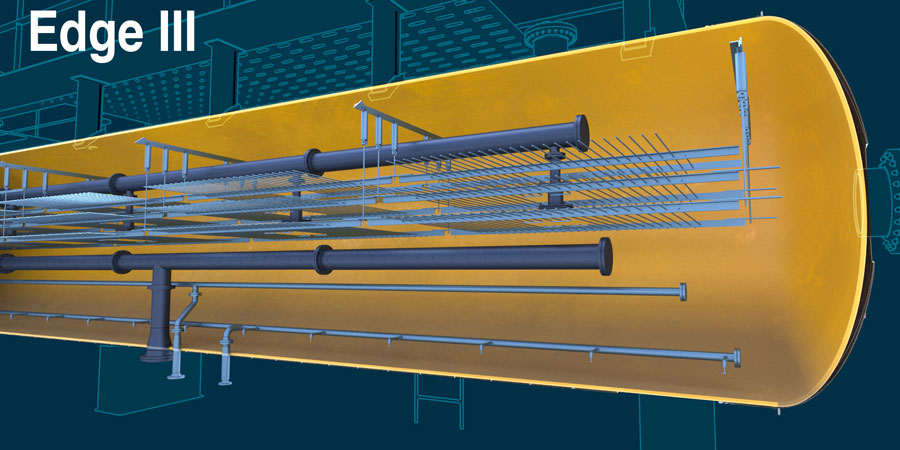

EDGE III

EDGE III combines all the applications of the EDGE/EDGE II distribution systems into the same vessel for a highly flexible design. As properties of the crude oil change, the combined distribution systems offer optimal processing.

NU-STATIC

Nu-Static supports processing of natural condensates, aromatics, reformer feed, virgin naphtha, distillates hydroxide, jet fuel/kerosene hydroxide, alkylate and distillates.