Components

FET Original Equipment Manufactured (OEM) ROV Components are specified not just by operators of Forum equipment but by other ROV manufacturers.

FET’s knowledge and expertise are utilized in the design of all our components ensuring they are suitable for the harshest of environments. This is why FET is the ‘go-to’ in the industry. FET’s range of OEM components includes Compensators, Pan and Tilt Units, Valve Packs, and Thrusters. Many of these components are available in a range of sizes and configurations to suit client-specific needs.

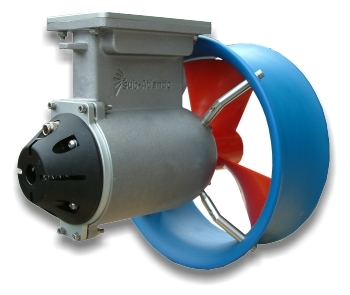

Thrusters

Sub-Atlantic offers the widest range of underwater vehicle thrusters available in the World. These include hydraulic and electric in both brushless DC and brushless AC types to suit most requirements. In certain applications, we can produce specials for customers requiring something outside of our range.

Hydraulic Thrusters

Sub-Atlantic’s range of hydraulic thrusters have become the preferred propulsion for ROVs and cable burial/maintenance vehicles. Working in a highly aggressive environment, they have earned a reputation for reliability, efficiency and exceptional performance.

- Proven Reliability – Low Parts Usage

- Efficient

- Forward/Reverse Thrust within 5% band

- Quick-Change Seal Cartridge

- Reliable Ceramic Sealing Surfaces

- Lightweight

- DNV Witnessed Performance

- Easily Retro-Fittable

- 4 Standard Propeller Sizes

- Various Interchangeable Motor Options

- Thruster Guards Available

Sub-Atlantic hydraulic thrusters are reliable due to a rugged, lightweight construction and a ceramic shaft sealing system. These thrusters also benefit from producing near equal forward/reverse efficiency within a 5% band. The data from our performance testing has been witnessed by DNV to ensure your system design performs exactly as expected. These thrusters also benefit from the ability to fit any motor displacement size to any of the four thruster sizes due to the common, one-size motor/thruster interface. This is advantageous when accurately matching to vehicle hydraulic system parameters.

Brushless DC Electric Thrusters

Sub-Atlantic’s direct drive range of brushless DC thrusters break new ground in thrust, low weight and enhanced reliability. They are currently available in three sizes, each incorporating Sub-Atlantic’s unique Statorshield™ technology.

- High Reliability, Rugged Design

- Unique StatorshieldTM Technology

- Continued Operation in the

- Event of Shaft Seal Failure

- Forward / Reverse Thrust within 5-10% Band

- Three Sizes Available

- Direct Drive Reliability (no gearbox)

- Lightweight Design

- Integral Drive Electronics

- Various Connector Options

- Various Voltage Options

Sub-Atlantic’s unique Statorshield™ system allows the thruster to continue running in the event of a shaft seal failure and subsequent flooding, without damage to the winding or electronic components. Integral electronic drives are oil-filled and pressure-compensated to 3000 metres / 10,000 feet. Three sizes are available with propeller diameters up to 246mm / 9.7” and bollard thrusts up to 100 kgf / 220 lbf.

Brushless AC Electric Thrusters

This range of brushless electric AC thrusters is used on our successful Mohawk and Super Mohawk ROVs. They are available in two sizes, the CTE-01 producing 29 kgf (64 lbs) thrust and the CTE-02 producing 45 kgf (100 lbs).

- Reliable

- Two Sizes Available

- Rugged Construction

- High Thrust output

- 440 Volts AC 50/60 Hz

- Direct Drive (no gearbox)

- Compact Drive Electronics

These thrusters are perfect vehicles using AC power transmission systems. Both sizes of thruster are direct drive for mechanical reliability and are proportionally controlled by an external drive electronics board designed to fit inside an electronics bottle with a minimum inside diameter of 166 mm / 6.5 inches. Power requirements are 415-440 Vac 3 Phase + Neutral, Control is +/- 5Vdc. These thrusters are positively oil compensated and rated for full ocean depth.

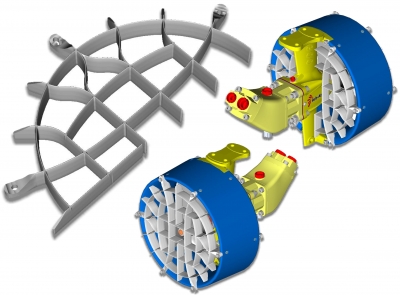

Thrusters Guards

A range of thruster guards in high strength, injected moulded plastic. The clever design shields both sides of the nozzle using four pieces of the same component. This single design allows us to minimise our tooling costs and pass the savings on to the customer.

- Economical

- Lightweight

- Efficient

- Strong Injection Moulded Plastic

- Retro-fittable

New thrusters will be supplied with guard-fixing holes incorporated in the nozzles. For existing systems, guards can be fitted by simply drilling and tapping nozzles on location.

Compensators

270cc, 370cc, 860cc and 2700cc Compensators

Forum’s Sub-Atlantic range of compensators allow for submerged systems to be flooded with incompressible fluid. They provide a positive pressure to a submerged oil filled component or system to protect against (sea) water ingress.

There are four sizes of rolling diaphragm, positive pressure compensators in corrosion resistant plastic suitable for ROV and tooling applications available with optional level sensors for volume monitoring.

The range of sizes available make these simple units particularly suitable for compensating thrusters, oil filled junction boxes, valve packs, etc.

13.5 Litre Compensator

Forum’s Sub-Atlantic 13.5 Litre / 3.6 USg positive pressure compensator is manufactured from plastic, stainless steel and aluminium alloy materials. It is available with an optional analogue level sensor.

Mean compensation pressure is 0.5 bar / 7 psi. An pressure relief valve, set at 1.3 bar, protects the unit from overfill and thermal expansion of the oil. Mounting feet are incorporated in the end caps. A compact analogue sensor that provides 0-100% level capacity feedback is available as a bolt-on option. Multiple compensators can be plumbed in parallel to increase total oil capacity using only a single level sensor. Ports are available in both SAE and BSPP versions

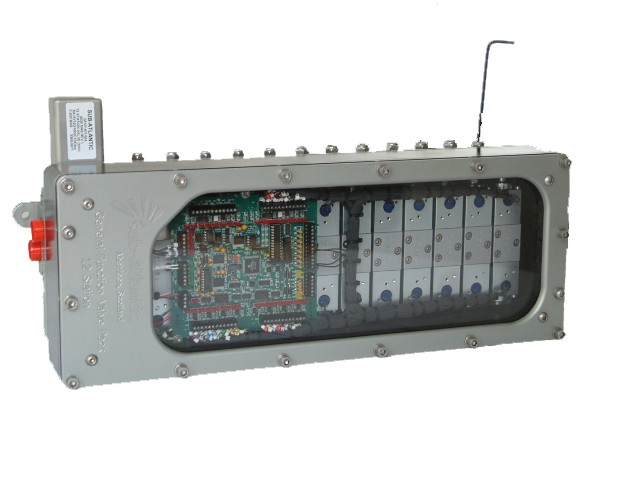

Valve Packs

General Function Valve Pack

Our General Function Valve Packs are the most compact and lightweight available. Loaded with functionality, solenoid, proportional or mixed valve configurations and driven by a powerful, fully configurable digital control system, these are the perfect choice for ROV and tooling applications. The Generation 2 valve pack are driven by a powerful, fully configurable digital control system that is compatible with Generation 1 units.

- 6, 8, 12 & 16 station versions

- Solenoid and/or Proportional Valves

- Wandfluh NG3 Valve Reliability

- Extremely Compact and Lightweight

- Manual or Prop. Pressure Reduction

- Externally Adjustable Flow Control

- Externally Adjustable Line Relief

- Removable/Configurable PO Check Valves

- Powerful Serial Control System

- Harware or GUI Control with Diagnostics

- Pressure Tolerant Electronics

- Pressure & Water Ingress Sensors

- Fully Captive Cover Screws

- Tested to 6,000 metres / 20,000 feet

The small size and weight of these valvepacks are achieved by building most of the functionality directly into the manifold body, thus avoiding many stacking ‘sandwich’ type valves. The heart of the system uses Sub-Atlantic’s unique Flow/PO Check Cartridge that combines a uni-directional flow controller and a pilot operated check valve. Typical operation includes manipulator functioning, adjustable torque tools, pan & tilt units, subsea robotics, etc. The small size and weight of these units make them additionally suitable for smaller electric ROVs where space and payload are at a premium.

The powerful serial control system drives either solenoid or proportional valves and can be independent or integrated into the customers overall control system.

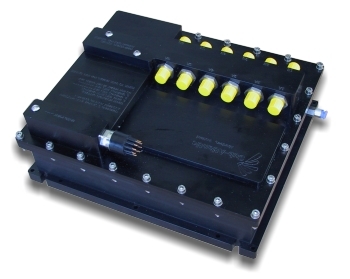

6 Station Combined HPU / Valve Pack

Sub-Atlantics 6 station valve pack has been designed for use on small electric ROVs using manipulators and/or tooling skids.

The unit incorporates a brushless DC motor (SPE-75 thruster motor), six Wand-fluh NG3 directional control valves, each with pilot-operated checks, and a mini-control system linked back to a single electrical connector. The 6 station Valve Pack will operate on AC 220V and 300VDC. The system provides smooth, reliable control over small hydraulic systems and any tool requiring low-power input.

8 Station Servo Valve Pack

This extremely compact servo valve pack weighs only 15 kg in sea and provides precise control of propulsion thrusters on underwater vehicles.

The pack incorporates eight 77 Lpm (20 US gpm) rated servo-valves that provide low pressure drop on most standard ROV applications. The use of this pack in conjunction with Sub-Atlantic’s efficient thrusters and Hydraulic Power Units will produce an unbeatable propulsion solution with regards to reliability, efficiency and cost. The valves can also be used to control any tool requiring a variable speed or reversible function.

Hydraulic Power Units

Hydraulic Power Unit - 1.3 kW

This small Hydraulic Power Unit (HPU) delivers 4 lpm / 1 usgpm at adjustable pressures up to 200 bar / 3000 psi and is suitable for powering manipulators, tools, etc.

- Adjustable Pressure Relief Valve

- Low Cost Replacement Pumps

- Integral Suction Filter

- 440Vac Operation

- Seal Between Motor and Pump

- Starts Under Load

A gear pump is driven by a 3 phase, 440 Vac electric motor, the same type as used on Sub-Atlantic’s reliable CTE-02 electric thrusters. An integral, externally adjustable pressure relief valve is used to set the system pressure and a quick-change suction filter cartridge is fitted into the body.

Pan & Tilt Units

Our electric and hydraulic pan & tilt systems are used on many sizes of ROVs, ranging from small electric, through work class to large trenching machines. Over a number of years, they have proven themselves to be reliable and durable in these difficult environments. We also include electric rotary actuators in this section that can be used for a large number of electric tooling applications.

Pan & Tilt Unit - 24 Vdc and 110 Vac

These pan & tilt units are used on a wide range of vehicle sizes from electric inspection class up to the largest cable plough. They provide a rugged and reliable alternative to hydraulic units.

- 24 Volts DC or 110 Volts AC

- Top Mounting Flange on Pan Shaft

- Low Backlash

- Self-Locking on Power Down

- Position Feedback

- Robust Design

- Adjustable Limit Switches

- Pressure Compensated

- Tested to 6000 msw / 20,0000 fsw

- Can be Inverted

With feedback potentiometers and adjustable limit switches supplied as standard, these rugged units are the perfect choice for the positioning of industry standard subsea cameras and sensors. The gearing system is overrated to resist damage due to collisions. Standard voltage is 24 Vdc but an optional 110 Vac is also available with pin-out to suit wellhead TV camera systems. Pan & Tilts are oil filled and positively compensated, making them suitable for operation at extreme depth and can be supplied with a range of electrical connector types.

Rotator / Tilt Unit - 24 Vdc

This versatile tilt / actuator unit is used on all our small electric ROVs for camera positions but also as a latching actuator in our TMS systems.

- 24 Volts DC or 110 Volts AC

- Top Mounting Flange on Pan Shaft

- Low Backlash

- Self-Locking on Power Down

- Position Feedback

- Robust Design

- Adjustable Limit Switches

- Pressure Compensated

- Tested to 6000 msw / 20,0000 fsw

- Can be Inverted

With feedback potentiometers and adjustable limit switches supplied as standard, these rugged units are the perfect choice for the positioning of industry standard subsea cameras and sensors. The gearing system is overrated to resist damage due to collisions. They are oil filled and positively compensated, making them suitable for operation at extreme depth and can be supplied with a range of electrical connector types.

Rotator Actuator - 24 Vdc x 50 Nm Torque

This electric rotary actuator delivers 50 N.m / 37 lb.ft torque from 24 Vdc supply. It is suitable for a wide range of actuation tasks and is available with an over-torque protection clutch.

- 50 N.m / 37 lb.ft Output Torque

- Self-Locking on Power Down

- Worm Drive Gears

- Continuous Rotation

- 24 Vdc @ 2.2 Amps

- Integral Oil Compensator

- Rated for 6000 msw / 20,000 fsw

- Adjustable Slipping Clutch Option

This rotary actuator can be put to many uses in subsea tooling, especially in small vehicles. One example is in our pipeline survey skid for inspection class ROVs where the actuator is used to raise and lower the camera boom and CP arms. The body is manufactured from lightweight aluminium alloy and shaft components are in stainless steel.