Float Equipment

Forum float shoes and float collars are simple in design and operation. They have been engineered and manufactured to withstand the high temperatures and pressures created by differences in fluid columns when floating, landing, and cementing strings of casing.

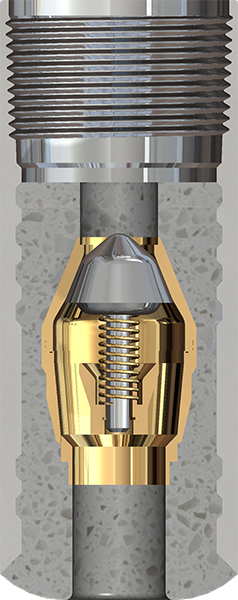

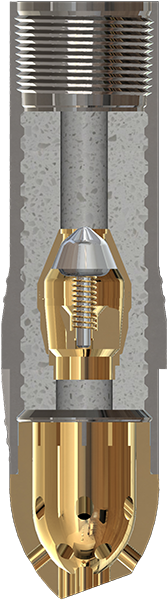

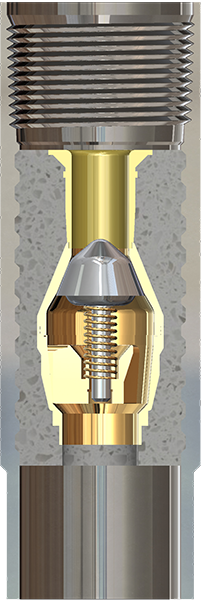

Forum’s standard design float shoes and float collars are manufactured with the PVTS valve. This valve is a spring-actuated, plunger-type, one-way check valve. It is designed to withstand high temperatures and large volumes of fluids pumped at high flow rates. It also provides an effective seal under both high- and low-pressure conditions when casing is run and cemented in either the vertical or horizontal position.

The valve housing and closure element are made with a phenolic material. High strength concrete is the compound that molds the valve in the machined housing to form a strong singular unit. Despite the high compressive strength of the concrete, and the shear strength of the valve, Forum float shoes and collars are easily drilled with conventional or PDC bits.

Because of its proven performance qualities, the PVTS valve is used in all manual-fill float equipment including double-valve shoes and collars, and all inner-string cementing equipment including the tag-in, screw-in, and latch-in designs.

Since Forum float shoes and float collars are usually manufactured from steel that has a greater wall thickness than the pipe body of the casing string they are run in, they normally have burst and collapse resistance greater than the casing string.

The Davis-Lynch PDQ Shoe Track™ system combines the shoe track into a 6’ single-piece unit with only one casing thread connection needed. Designed to improve open toe cementing and frac completion well designs, the PDQ system is comprised of a 15K back pressure rated four (4) valve system, latch-down wiper plug profile, guide nose options of rounded or eccentric design type made of composite or aluminum materials. Additional options of reamer blades or jetted profiles are also available. The one-piece external case body is designed with a lifting neck profile for ease of safe handling and installation on the rig floor.

FEATURES

- Designed and manufactured in the USA, ensuring premium quality and timely delivery

- Industry proven 15K pressure rated dual double PVTS valve configuration

- Built-in latch-down plug landing receptacle profile for use with FDL latch down wiper plug systems with multiple landing seats for use with multiple size dissolvable balls

- Choice of many high-performance float shoe nose designs in aluminum and composite materials

- Reamer shoe and jetted Nose configuration options also available

- Available in PDC drillable Davis-Lynch PVTS aluminum valves or severe service cast iron valves for extreme well bore conditions, for use with heavy mud weights and high BHST well temperatures

BENEFITS

- Reduction in cost of threaded connections ($1200 – $4000 minimum savings)

- Provides optimal reduced length shoe track integrity (6’ +/-)

- For use with anticipated high differential pressures when running casing and at the end of primary cementing displacement

- Increases usable pay zone length

- Improves shoe joint integrity and reduces leak points in the casing string

- Four (4) reliable top fill float check valves that provide well control while running casing

- Eliminates need for separate landing collar for latchdown wiper plugs

- Compatible with all mud types (WBM, OBM, and SBM)

- Provides well test set-up options for completion operations

DESIGN HIGHLIGHTS

- A one-piece design with only 1 (one) casing thread make-up connection

- The design includes an OD profile to provide a lifting neck to allow for easy rig handling and casing string make-up on the rig floor

- Designs can match most casing grade materials and casing threads

- Dual Double 15K psi high back pressure float valve design (4 valves) ensures positive sealing in vertical, horizontal, and deviated wells with a mechanically retained viton coated poppet valve and protected valve spring

- Built from field proven Davis-Lynch PVTS Float Valves that have been tested to API 10F Test rating of D24-R10-T400-P15

- The PDQ design covers casing sizes of 4-1/2”, 5”, 5-1/2” and 6”, with larger casing sizes available by request and further design

- Exceptional quality built with full traceability of component materials starting from the mill material certificates to well site delivery

FlowSure™

The FET Davis-Lynch new FlowSure™ Float Equipment is designed to maximize reduction of surge pressure when running close-tolerance casing or liners (small annulus). The valve features a large inside diameter to maximize conversion drop ball size. The larger ID allows for longer circulation with harsher fluids at greater pump rates. The larger ID is also less likely to bridge off during run in hole. Precise conversion pressures are factory adjustable from 300psi to 3,000psi, although most prefer a low conversion pressure of 600-900psi. All this with most components made from an easily drilled composite (glass-reinforced epoxy resin) material.

RECOMMENDED CONFIGURATIONS

The recommended configuration for FlowSure™ float equipment is a doublevalve float collar run in conjunction with a guide shoe. This configuration allows for a one or two joint casing shoe track and is more tolerant of large amounts of cuttings or debris entering the casing string. The guide shoe can be configured with angled jets to aid in cement distribution; eccentric noses are available as required. The guide shoe has a composite rod across it’s bore to prevent the piston or tube of the float collar from possibly blocking the flow.

This equipment can be ordered in a Multi-Purpose Float Collar (Type 713-MP) and we suggest it be run with a Cement-nosed Guide Shoe (Type 601 down-jet or Type 602 up-jet) configuration. It is available in sizes 4-1/2” and larger. For extremely heavy weights of casing, please consult engineering to confirm that normal valve/ball/seat configurations can be used.

The valve is roughly 90% composite (plastic) material and 10% cast-aluminum by weight. The only aluminum components remaining are the flappers, the top portion of the piston, the ball seat, and the ring which holds the shear pins.

500 Float Shoe

The Davis-Lynch™ 500 float shoe features PVTS check valves which will withstand 24 hours of circulating time with 12 ppg fluid at 10 bpm, and is rated to 5,000 psi back pressure at 400°F. Since Forum’s purchase of Davis-Lynch over 21,000 500 series float shoes have been run.

Applications

- Conventional cement jobs onshore and offshore

Benefits

- PDC drillable

- PVTS check valve withstands long circulation time

- High back-pressure rating at temperature

Features

- Rounded cement nose

- High quality PVTS plunger style check valve

- Manual-fill

Options

- Double valve

- Eccentric nose

- Needle nose

- Lug nose

- Up-jets

- Auto-fill

500RM ReamMaster Reamer Shoe

The Davis-Lynch™ 500RM ReamMaster Reamer Shoe features PVTS check valves, milled angled ribs, and an eccentric round nose. Downjet ports improve circulation, turbulence and even distribution for well cementing applications even in challenging conditions. Since Forum’s purchase of Davis-Lynch over 500 Reamer Shoes have been run.

Applications

- Onshore and offshore wells with unstable formations

Benefits

- Rotation and reciprocation capable, but not required

- Provides superior performance to get casing down through unstable formations

- Not a drill-shoe and will not make a new hole

- PDC drillable

Features

- Eccentric round nose

- Non-aggressive milled ribs with hard-banding

- Manual-fill

Options

- No valve – guide shoe

- Double valve

- Composite nose

- Auto-fill

501 Float Shoe

The Davis-Lynch™ 501 float shoe features PVTS check valves and standard cement noses and non-standard noses. Down-jet ports to improve circulation, turbulence and even distribution of fluid for well cementing

applications even in challenging conditions. Since Forum’s purchase of Davis-Lynch over 7,750 501 series float shoes have been run.

Applications

- Conventional cement jobs onshore and offshore

Benefits

- Boosts turbulence for cementing

- Improves circulation for trouble spots

- Helps wash casing to the bottom

- Reduces risk of casing plugging

- PDC drillable

Features

- Rounded cement nose

- Multiple down-jet ports

- Manual-fill

Options

- Double valve

- Eccentric nose

- Needle nose

- Lug nose

- Up-jets

- Auto-fill

501DV Float Shoe

The Davis-Lynch™ 501DV float shoe features PVTS check valves and standard and non-standard cement noses.

Down-jet ports improve circulation, turbulence and even distribution of fluid for well cementing applications even in challenging conditions. Since Forum’s purchase of Davis-Lynch over 5,000 501DV float shoes have been run.

Applications

- Conventional cement jobs onshore and offshore

Benefits

- Provides more security than single valve options

- Boosts turbulence for cementing

- Improves circulation for trouble spots

- Washes casing to the bottom

- PDC drillable

Features

- Rounded cement nose

- Multiple down-jet ports

- Double valve design to maximize protection

- Manual-fill

Options

- Eccentric nose

- Needle nose

- Lug nose

- Up-jets

- Auto-fill

501ECN Float Shoe

The Davis-Lynch™ 501ECN float shoe features PVTS check valves and an eccentric nose. Down-jet ports

improve circulation, turbulence and even distribution of fluid for well cementing applications even in challenging conditions. Since Forum’s purchase of Davis-Lynch over 3,000 501ECN float shoes have been run.

Applications

- Challenging onshore and offshore hole conditions that necessitate a non-standard nose profile

Benefits

- Rotates/bounces past ledges or obstructions

- Nose design better navigates adverse conditions for running casing

- Both aluminum and composite nose options are

PDC drillable

- Improves circulation for trouble spots

- Washes casing to the bottom

Features

- Off-center slimmed nose design

- Multiple down-jet ports

Options

- Double valve

- Up-jets

- Aluminum or composite nose

- Auto-fill

700 Float Collar

The Davis-Lynch™ 700 series float collar features PVTS check valves and is equipped with a flat cement surface for landing and sealing cement plugs. Since Forum’s purchase of Davis-Lynch over 24,000 700 series float collars have been run.

Applications

- Conventional cement jobs onshore and offshore

Benefits

- Superior cement plug sealing surface

- PVTS check valve increases circulation time

- High back-pressure rating at temperature

- PDC drillable

Features

- Load distributor plate for landing and sealing cement plugs

- Box and pin connections standard

- Manual-fill

Options

- Double valve

- Auto-fill

700X - DSEH Profile Float Collar

For subsurface launch applications, Forum has partnered with Schlumberger to provide the 700X – DSEH (Deep

Sea EXPRES* Head) Profile Float Collar. It features an engineered cement sheath that can house both a bottom and top DSEH plug that, once in place, prevents rotation during drill-out. Since Forum’s purchase of Davis-Lynch over 1,400 700X series float collars have been run.

Applications

- Subsurface Schlumberger DSEH plug launch applications

Benefits

- Provides anti-rotation for DSEH plugs

- Faster drill-out times

- PVTS check valve increases circulation time

- High back-pressure rating at temperature

- PDC drillable

Features

- Cement Sheath for DSEH plugs

- PVTS check valve

- Manual-fill

Options

- Double valve

- Auto-fill capable

HP HT Float Equipment

Operators face many challenges with well construction designs in achieving satisfactory zonal isolation during the cementing process. Challenges with high-pressure formations requiring heavy mud weights, long horizontal legs utilizing Casing Flotation Tools, and setting the well up for later frac stimulation treatments during the casing running process utilizing Frac Sleeves and Wet Shoe Cementing processes.

Most of these conditions require a need for High-Performance Float Valve Equipment that exceeds standard flow and back pressure ratings of standard Composite Float Valves.

Davis-Lynch has the solution for these needs with our 15K Back Pressure Rated 500H Float Shoe and 700H Float Collar.

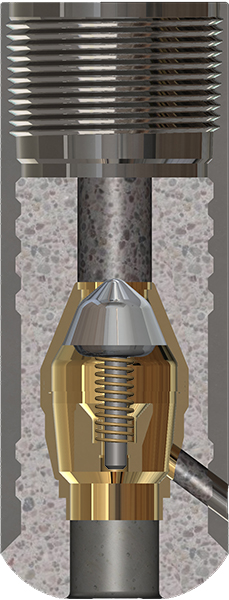

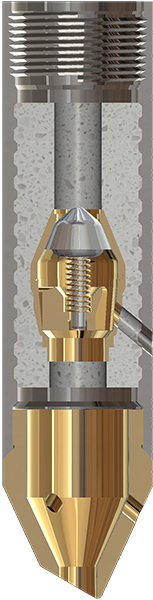

Design

- 15K Rated Mechanical Poppet Valves fabricated from high strength metallic materials (drillable and non-drillable)

- Special Seal Designs for longer sealing capabilities and valve life expectancies

- Fully Covered Viton Rubber Coated Valve Poppet

- Built to exceed API Spec 10F D24 (24hrs flow)- R10 (10bpm flow rate)- T400 (400 DegF)- P7.5 (7500 psi back pressure)

- API Q1 manufactured with full traceability of all components

- USA Manufactured at our Pearland, Texas Manufacturing Facility

- These heavy-duty valves offer positive sealing regardless of back pressure in vertical, deviated, and horizontal wellbores.

Features

- Available in sizes from 4-1/2” to 7”. Other sizes custom built by request

- Available in most Material Grades and Casing Threads

- Available in Aluminum Valves and Seats, Cast-Iron, or CRA Material designs for the most severe service well conditions

- Available in Single and Double Valve Configurations

- 4 Valves Standard in our One-Piece PDQ Wet Shoe Track System

- Numerous Float Shoe Noses available (Composite or Aluminum materials, Rounded, Tapered, Jetted, and with Reamer Blades)

- Float Collar designs available with Latch-in Plug Receptacles for use with matching Latch-in Wiper Plugs

Benefits

- Reliable Top Fill Float Valves for ultimate well control when running casing and preventing casing flow back after primary cementing

- For use with high differential pressures expected at end of Cementing displacements, during Casing Flotation Operations, and Wet Shoe Cementing Process

- Compatible with all mud types (OBM, WBM, SBM)

- Provides ultimate shoe track integrity

- Allows for use with heavy weight muds

- Drillable with PDC bits (excluding Cast Iron or CRA Material valves)