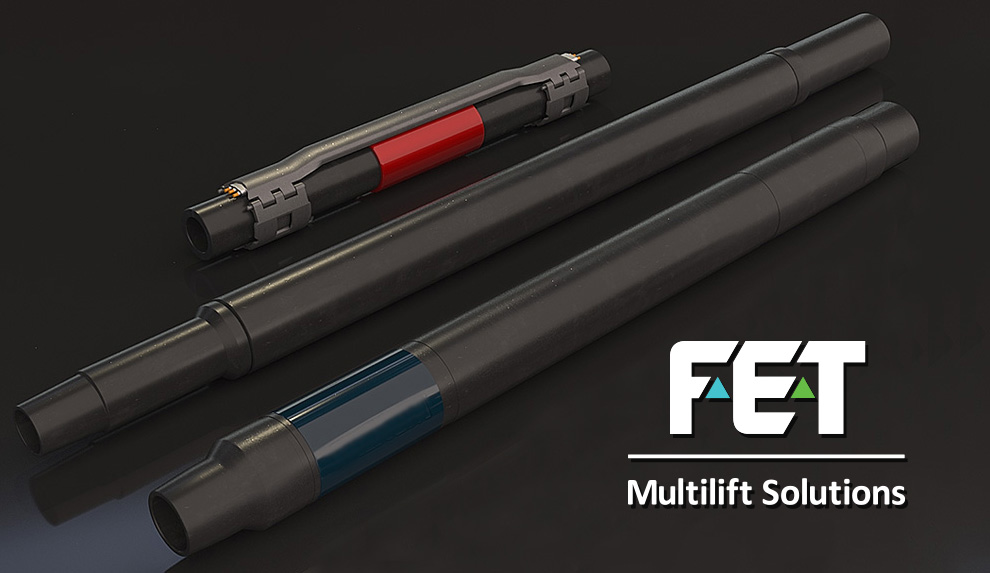

The Electric Submersible Pump (ESP) artificial lift system utilizes an electric motor to power a multistage centrifugal pump, lifting fluids from oil wells. Sub-surface components include a sensor, electric motor, seal chamber, shaft, pump intake, and centrifugal pump stages. Surface components involve electrical supply equipment, an ESP controller, and a variable speed drive. ESPs are adaptable to deviated wells, operate quietly with a small footprint, handle high volumes, and work in corrosive environments. However, they face challenges with solids, removal costs for downhole failures, efficiency at lower volumes, and casing size requirements for higher production rates.