SPD Drill Pipe Float Valves

In 2006, Forum purchased the Baker SPD product line. Forum continues to manufacture the products formerly known as Baker SPD under the SPD name and offers a complete line of float valves, repair kits, and puller assemblies for a wide range of drilling situations and operating conditions. We are the premier provider of “Certified” drill pipe float valves that includes high- and low-pressure testing, serialization, and full material traceability, providing improved reliability and failure prevention.

High-performance drill pipe float valves are essential for consistent fluid control throughout drilling. Also known as non-return valves, this type of downhole safety valve prevents undesirable fluids from backing up into the drill string any time your crew is modifying connections.

Our Valves

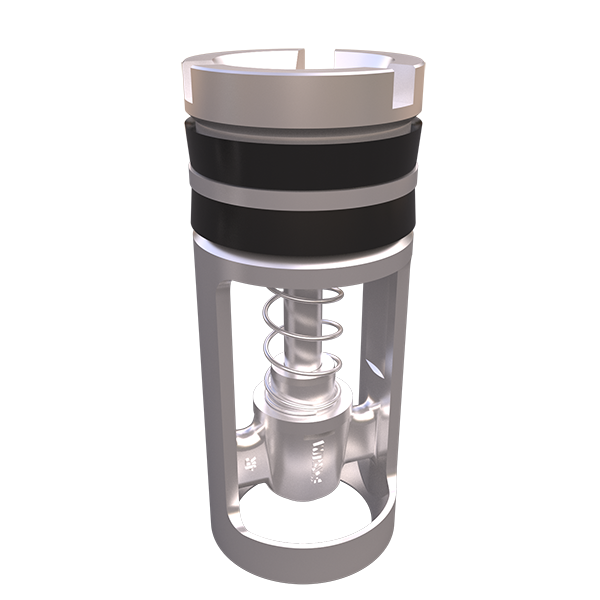

Models F/FA

The Model F plunger-type valve provides positive, instantaneous shutoff against high and low pressure, assuring continuous control of fluid flow during drilling. This durable valve is the most economical choice for normal drilling operations and is recommended for use with downhole mud motors.

Model FA offers all standard features of the Model F float valve with the addition of a port that allows automatic partial filling of the drill pipe during run-in. This valve is used when monitoring the bit head for gas pressure and/or as pockets allowing measurement of differential pressure when required.

Features

- Sizes 1R-6F

- Plunger-type valve

- FA: ported style/differential monitoring

- Standard/hydrogen sulfide (H2S) service

- High-temperature/geothermal service

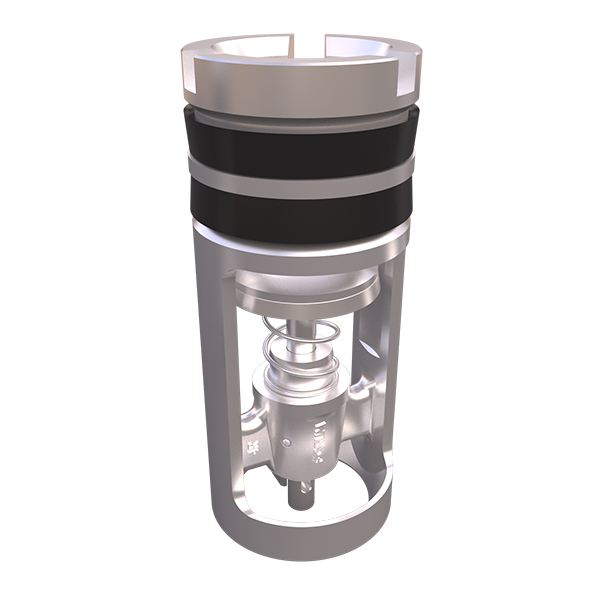

Models FC/FCA

Ideal for drilling deep wells, the Model FC automatic fill valve allows the drill pipe to fill from the bottom and removes the mess, hazards and lost time from filling. The automatic-fill feature also eliminates the “ram effect,” preventing downhole pressure surges that can cause formation damage.

Features

- Sizes 2F3R-6F

- Auto-fill feature

- FCA: ported style

- Standard/H2S service

- High-temperature/geothermal service

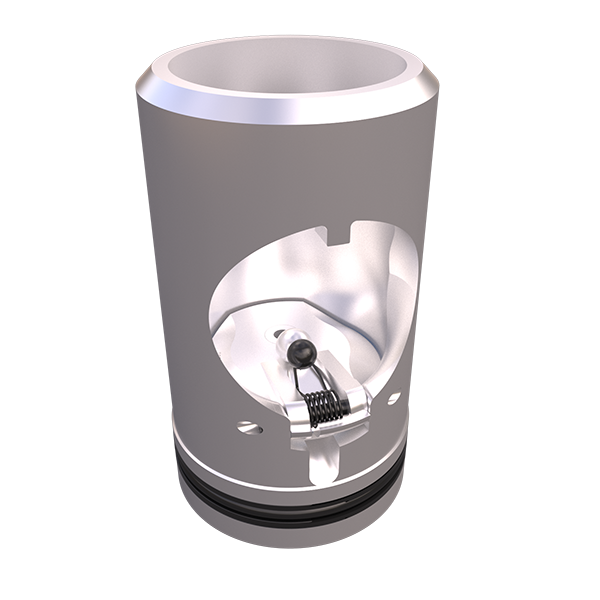

Models G/GA

Especially suited to highly abrasive fluids, the Model G flapper-type full-open valve opens quickly and fully to provide a completely unrestricted bore through the valve. When circulation stops, the flapper closes instantly to prevent cuttings from entering the drill string and plugging the bit.

The Model GA differential pressure monitoring valve offers all standard features of the Model G and includes a flapper insert to provide automatic partial filling of the drill pipe during run-in.

Features

- Sizes 1F2R-5F6R

- Flapper-style valve

- GA: ported style/differential monitoring

- Standard/H2S service

- High-temperature/geothermal service

Models GC/GCA

The Model GC automatic-fill flapper valve uses a low-carbon steel automatic-fill key assembly that allows the pipe to fill from the bottom, reducing run-in time by eliminating the need to fill the string from the top. This fast-acting valve helps reduce the possibility of pulling a wet string – along with the associated safety hazards – and eliminates mud spill-over on the rig floor.

Model GCA incorporates the benefits of Models GC and GA, allowing automatic partial filling of the drill pipe from the bottom. This eliminates the need to fill the string from the top when running in the hole and measuring differential pressures when required.

Features

- Sizes 1F2R-5F6R

- Auto-fill feature

- GCA: ported style

- Standard/H2S service

- High-temperature/geothermal service

Models GS/GAS

Models GS and GAS drill pipe float valves offer optimum performance and reliability for jobs that require high flow and erosion resistance. Available in standard and non-standard configurations, both models are machined to strict tolerances that help minimize fluid wear and streamline flow.

Features

- Sizes 3.38×2-5F6R

- Large inner diameters for high flow rates

- Alloy steel for erosion resistance

- Compact design, ideal for mud motor applications

- GAS: ported style/differential monitoring

Certified Drill Pipe Float Valves

Drill Pipe Float Valves are considered a critical component in the drill string. Drilling specifications and requirements are becoming more demanding in today’s drilling environments. Reliability and failure prevention are now a key objective for operators when drilling critical wells.

Forum Energy Technologies is the leading manufacturer of fully Certified Drill Pipe Float Valves. Each valve is tested in both low and high-pressure settings. Serialization, full traceability and complete documentation are standard for each certified valve.

Operators will have the confidence of knowing that each Drill Pipe Float Valve put downhole has been fully tested and documented; which will reduce NPT and minimize HSE risks.

Features & Benefits

- Each valve is pressure tested: High (7500psi) and low (300psi)

- Serialization

- Full traceability on components

- Fully Certified documentation package

- Most common sizes in both Model F/FC/FA & G/GC/GCA/GA configurations

- Both HSN and Viton elastomers available

- 10K models available

- Valves available conforming to the new API 7V standard

- In-house flow testing capabilities with mud