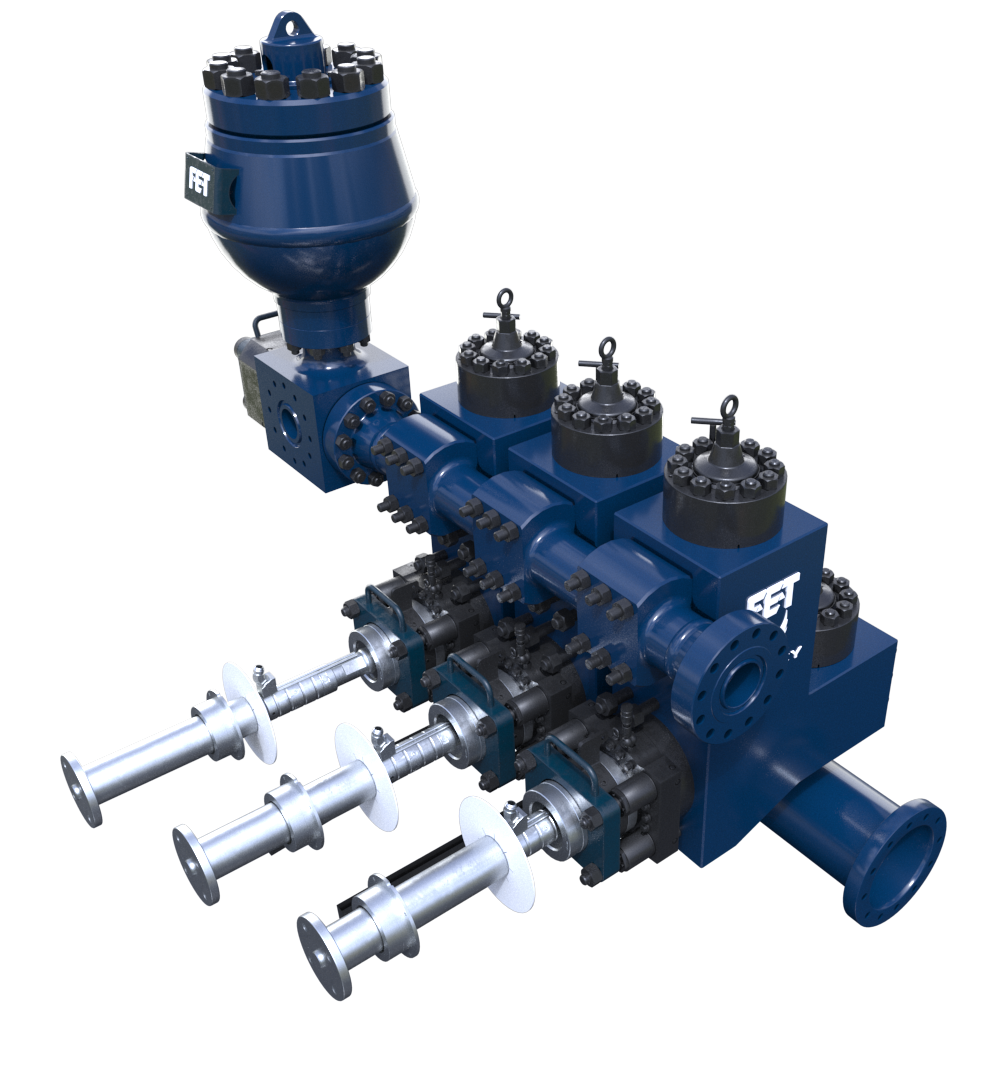

Fluid End Modules

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

- Significantly reduced internal stresses

- Banded Bore™ technology for selected configurations

- Machined from 4130 forged heat-treated material

- Rated working pressure of 7,500 pounds per square inch (psi)

- Two-piece, L-shape, valve-over-valve and mono-block for well service available

- Configurations to fit virtually all pump manufacturer designs

Fluid End Module Repair & Refurbishment

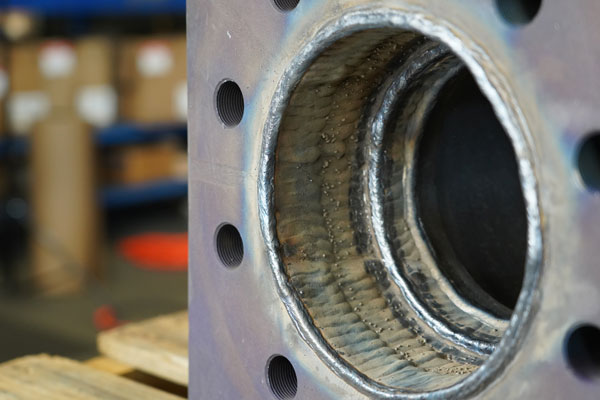

Fluid End modules are subject to high pressure, abrasion, corrosion, and fatigue, which can cause damage and reduce their performance and lifespan. It is important to repair and refurbish fluid end modules regularly to ensure optimal efficiency and safety.

FET will inspect, clean, replace, and restore the parts that are worn out or damaged on modules. Our standard process includes:

- Identifying the make and model of the fluid end module.

- Different types of modules require different repair and refurbishment methods and techniques. This first step is critical to determine the best procedure for your module repair.

- Removing the damaged parts, cleaning, and sandblasting for module evaluation.

- Evaluating the condition of the fluid end modules and identifying any internal damage, such as cracks/indications, washouts, thread damage, or internal surface damage.

- Restoring the fluid end modules to their original shape and size by using proprietary welding and machining processes, depending on the extent and type of damage.

Repairing and refurbishing fluid end modules will extend their service life, reduce your overall capital expenditure, and improve the performance and reliability of the mud pumps. FET is equipped to repair all types fluid end modules, including one-piece, two-piece, L-shaped, or valve-over-valve.