Pressure Gauges

Compound Pointer Pressure Gauge

Dual-pointer pressure indicator systems deliver accurate measurements for mud, cementing, acidizing, and fracturing operations

Forum Compound Pointer Pressure Gauge systems accurately measure and display pump pressures for downhole cementing, high-pressure hydraulic fracturing, or acidizing oil pay operations.

A standard pointer provides a full 360° sweep of the dial, and a vernier pointer offers 4 to 1 resolution for indicating even small pressure changes. The system consists of a 6-inch Pressure Gauge, a Gauge Protector, and a high-pressure Hose.

Features

- Standard capacities include:

- 4,000, 8,000, 12,000, and 16,000 psi

- 400, 800, 1200 kg/cm²

- 40, 80, 120 MPa

- Durable 517-152 Gauge Protector mounts with

2-inch NPT sub - Operational in temperature ranges of -50° to +150° F

(-45° to +65° C) - Accuracy rate of ± 1.0% of full indication

- Available in box-mount and panel-mount configurations

- Standard 50-foot hose, with other hose lengths available

Benefits

- Gauge can be mounted in any convenient location — perfect for use on service trucks.

- Vernier pointer provides 4 times more resolution for the same pressure change — measuring small pressure changes caused by formation breakdown, perforation plugs, and fractures.

- Fluid-filled gauge protects readings from truck or rig vibration.

- Operator-adjustable controls enable steady pointer movement.

- Provides all the advantages of the standard pump pressure gauge, with the added accuracy of the vernier pointer.

- Measurements can be easily recorded by hydraulic circular recorders or electronic remote strip recorders.

To order specify

- Application

- Required capacity

- Required hose length

- Gauge mounting

Pressure Gauge

For hose lengths over 50 feet, the Forum 517038 1:1 Piston Separator can be used

Gauge Protector

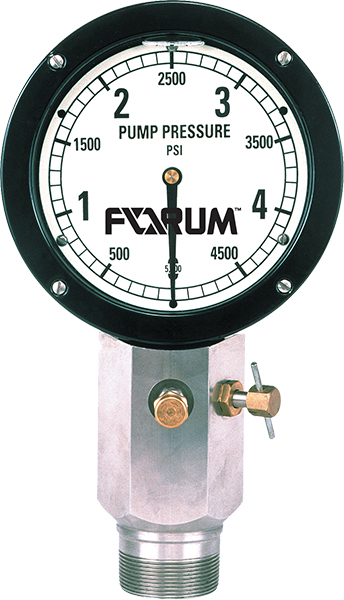

Single Pointer Pressure Gauge

Gauge provides quick, accurate check of mud pump operation

Forum Single Point Pressure Gauge systems help detect mud pump operation problems, such as washed out drill pipes. This convenient gauge can be mounted in a weight-indicator box on the drillers console, or on the mud pump. The system consists of a 6 inch Pressure Gauge a Gauge Protector and a high pressure hose.

Features

- Standard capacities include:

- 3,000, 5,000, 6,000, 10,000, and 15,000 psi

- 210, 350, 420, 700, and 1,000 kg/cm²

- Also available in kPA, MPa, and BAR capacities

- Durable 517-152 Gauge Protector mounts

with 2-inch NPT sub - Standard 50-foot hose, with other hose lengths available

Benefits

- Easy to mount in a variety of locations: in a weight-indicator box, in the driller’s console, or on the mud pump.

- Full 360° dial calibration accurately indicates small pressure changes.

- Fluid-filled gauge protects readings from truck

or rig vibration. - Large, easy-to-read 6-inch, fluid-filled dial face.

- Operator-adjustable high-pressure damper ensures accurate readings.

To order specify

- Application

- Required capacity

- Length of hose from sensor to gauge

- Gauge mounting

Pressure Gauge

For hose lengths over 50 feet, the Forum 517038 1:1 Piston Separator can be used

Gauge Protector

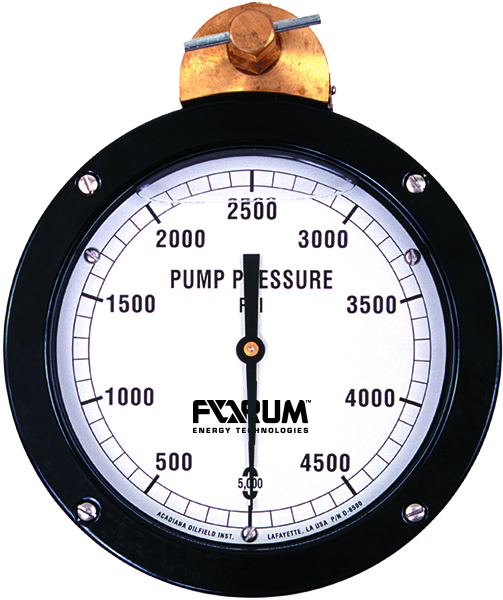

Standpipe Mud Pump Pressure Gauges

Forum standpipe type Mud Pump Pressure Gauges are available for a variety of capacities and operating conditions:

-

- Model F Gauge for capacities up to 20,000 PSI

- Model D Gauge for capacities up to 6,000 PSI

Model D Gauge

Model F Gauge

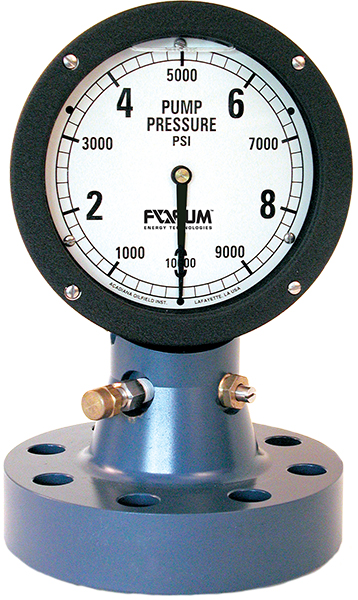

Unitized Pressure Gauge

Rugged gauges can easily be read from 60 feet away or more

The easy-to-read Forum Unitized Pressure Gauges indicate mud pump pressure and standpipe pressure. These gauges can be used on cementing, acidizing, fracturing, and gravel-packing trucks.

- Standard capacities (psi) include:

- 0 – 1,000

- 0 – 3,000

- 0 – 5,000

- 0 – 6,000

- 0 – 10,000

- 0 – 15,000

- and metric equivalents in kg/cm2, KPa, MPa, and BAR units of measure

- Large 6-inch dial face

- Mounting: 2-inch male NPT

- Weight: 16 pounds

- Rugged 17-4 PH stainless steel gauge body

- Diaphragm or bronze piston with Quad Viton seals

- Fluid-filled case lubricates moving components and the pointer damper, for increased reliability and reduced maintenance costs.

- Integral operator-adjustable damper eliminates pointer oscillations.

- Replaceable diaphragm, and checkvalve for loading fluid make on-site service easy.

- Hexagon-shaped gauge body for easy mounting.

- Bourdon tube and movement indicator gives highly accurate readings of mud pump and standpipe pressure changes.

UFPG Gauge

UHPG Gauge

UPG Gauge

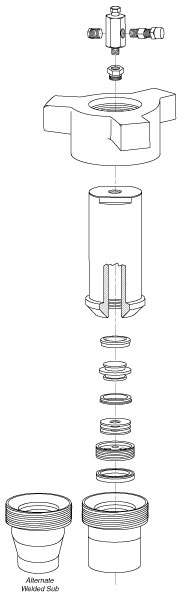

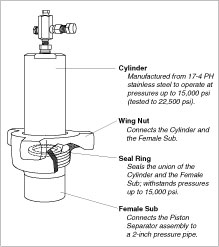

Piston Separator

Transfers pressure readings to gauges and recorders in remote locations

The Forum 517038 Piston Separator is a 1:1 ratio device that transfers well fluid pressure (such as cement, acid, and mud) to a remotely located gauge or recorder.

The Piston Separator handles working pressures up to 15,000 psi delivered through a ¼-inch high-pressure hydraulic hose.

Specifications

- Working pressure up to 15,000 psi

- Proof test pressure ratings made at 150% of working pressure ratings

- Volumetric capacity (full stroke): 13.4 cubic inches (220 cubic cm)

- Mounting pipe size: 2-inch

- Dimensions:

- Height: 13.5 inches (34.3 cm)

- Width: 7 inches (17.8 cm)

- Weight: 28 pounds (12.7 kg)

Piston Separator Models

| Model | Maximum Working Pressure | Description |

|---|---|---|

| 517038-1 | 15,000 PSI | Separator with welded female sub |

| 517038-2 | 10,000 PSI | Separator with threaded female sub |

| 517038-3 | 15,000 PSI | Separator without sub |

| 517038-4 | 10,000 PSI | Separator with welded female H2S sub and nut |

| 517038-5 | 10,000 PSI | Separator without sub, with H2S nut |

| 517038-6 | N/A | Separator only, with nut and female sub of your choice |

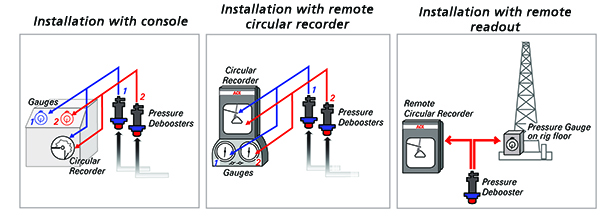

Pressure Deboosters

Essential for enabling accurate readings from pressure gauges, transducers, and recorders

Forum offers a complete line of pressure reduction sending units (PRSUs). These pressure deboosters reduce line pressures associated with fracturing, cementing, and testing operations by a ratio of 4 to 1 – a 75% reduction that enables pressure measurements to be safely sent to pressure gauges, transducers, and recorders.

Features

- Highly accurate – delivering an accuracy rate of ± 2% of full scale.

- Ideal for use with Forum pressure gauges, transducers, and recorders, which are calibrated for use with Forum pressure deboosters.

- Available in a variety of models, so you can choose the perfect solution for any job.

Specifications

- Reduces line pressure by a ratio of 4:1 (75%).

- Models available for a range of maximum incoming working pressures (psi):

- 10,000

- 15,000

- 20,000

- Available in standard service or H2S service models

- Enables transmission of pressure readings over a distance of up to 100 feet

- Viton isolator seal

- Operating temperature range:

- -35 to +150 degrees F

- -37 to + 65 degrees C

- Dimensions:

- Height: 13.5 inches (34.3 cm)

- Width: 7 inches (17.8 cm)

- Weight: 34 pounds (15.88 kg)

Pressure Debooster Models

| Model | Service Type | Max. Working Pressure | Proof Test Pressure | Hammer Union |

|---|---|---|---|---|

| PRSU-15-S | standard | 15,000 psi | 22,500 psi | 1502 |

| PRSU-20-S | standard | 20,000 psi | 30,000 psi | 2002 |

| PRSU-10-H | H2S | 10,000 psi | 15,000 psi | 1502 |

| PRSU-15-H | H2S | 15,000 psi | 22,500 psi | 2202 |

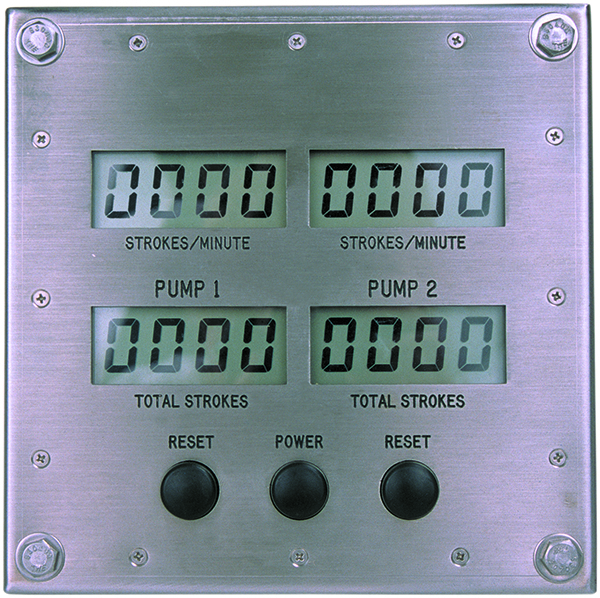

Pump Stroke Counter / Rate Meter

Monitors and displays number of strokes and stroke rate for two mud pumps

The Forum Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for two mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count. A stainless steel enclosure ensures reliable readings even in the toughest operating environments.

Features

- Displays total number of strokes — from 0 to 9,999

- Displays number of strokes per minute — from 7.5 to 1,024

- Low current consumption — approximately 100 uA in standby mode

- LCD display height: 0.7 inch

- Operates in temperatures from -4° to 140° F (–20° to 60° C)

- Size: 7-7/8″ H x 7-7/8″ W x 3″ D

- Weight: 4 pounds

- Available model that meets Class 1, Division 1 standards

- Displays strokes for 2 mud pumps (Optional model available that displays strokes for 3 mud pumps)

Benefits

- Battery powered — no external power required.

- Low energy use adds the extra benefit of an intrinsically safe design.

- Stainless steel enclosure ensures accurate readings in harsh environments.

- Easy-to-read display and easy-to-use control buttons.

- Low maintenance, with a long life expectancy of 50,000 hours of continuous use.

- Requires no calibration.