Subsea Engineering

Forum’s subsea engineering business offers full design and fabrication services for a significant range of pipeline products aimed at the petrochemical, process, offshore, and subsea installations. Forum’s Moffat products have a class leading reputation with strong global client list to match.

Forum’s manufacturing facility for Moffat products is located in Kirkbymoorside. The plant offers full in-house design, fabrication and testing services for a significant range of pipeline products aimed at the petrochemical, process, offshore, and subsea installations.

The plant has world class welding facilities, accredited to BS EN ISO 3834 Part 2. Forum has a large library of prequalified weld procedures, qualified in accordance with all major oil companies’ specifications. In addition Forum regularly and consistently performs bespoke weld procedures for permanent and subsea works. All welders are fully coded and can work with the materials and to the standards as follows:

- Material Grades: Carbon Steel, AISI 4130, S/ Steel 316L, Duplex UNS 31803, Super-duplex UNS 32760- 32750, Inconel 625 & Nitronic 60

- Standards: ASME IX, AWS D1.1, BS EN 15614,BS EN 4515 PART 1&2 & DNV-OS-F101

- Processes: GTAW, SMAW, GSFCAW & SAW

Pig Retainers

The Moffat Pig Retainer™ (sometimes known as a Pig Lock) provides a reliable mechanism to prevent pigs moving inside a pipeline during Pig Launcher / Receiver installation and removal operations. A high yield pin is extended and withdrawn into the barrel by means of a Remote Operated Vehicle (ROV) rotary interface. This pin reacts against the nose of the pin to hold it in position during deployment or retrieval. Depending on the pig size, the pin can retain a pig under a differential pressure of up to 10 BAR.

Key features:

- Suitable for up to 36” NB Pipeline

- Pressure rated up to 15,000 psi

- Range of materials options for temporary and permanent service

- Various ROV interfaces available

Surplussing Valves

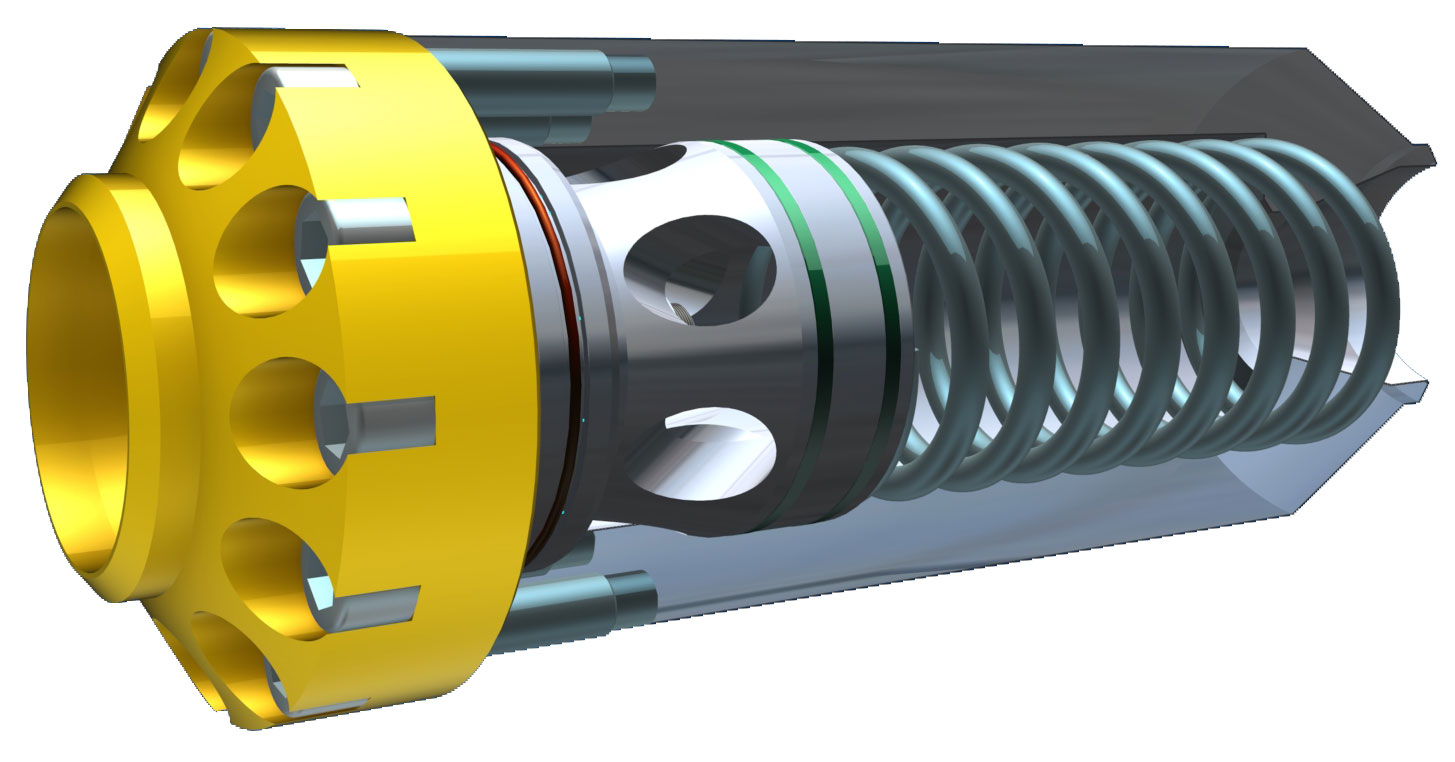

Moffat Surplussing Valves™ are a variable cracking pressure check-valve. They are a time proven solution in preventing the collapse of hoses due to external pressure.

Key Features:

- Compact inline design check-valve.

- Prevents hose collapse due to external pressure.

- Variable cracking pressure; in excess of 100 Bar possible.

- Available up to 8″ Nominal Bore.

- Range of materials options for temporary and permanent service

- Easy to service and maintain.