Centralizers & Accessories

Solid Body

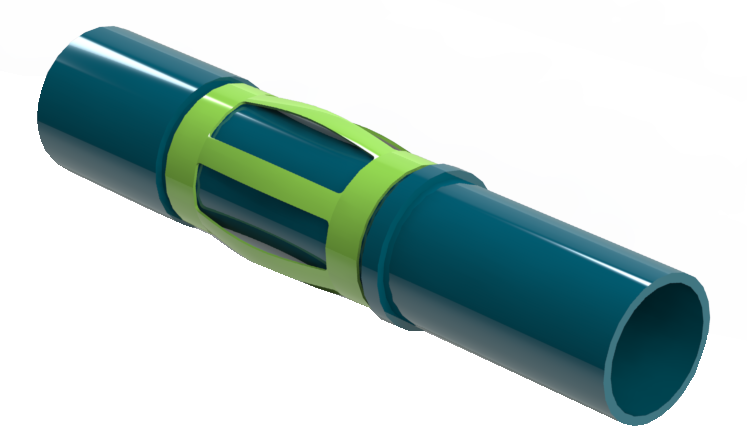

Welded Hollow Vane Spiral Centralizer

In applications for running casing or liners in unstable boreholes and rotation is desired, Davis-Lynch™ offers a special type rigid centralizer for these requirements. To provide optimum performance in unstable wellbores, Hollow-Vane centralizers feature positive stand-off, yet intentionally yield at a pre-determined side-force to prevent stuck-casing. These centralizers have a solid type end collar for slipping over the pin end of the casing joint.

Features/Benefits

- Made of steel to provide rigidity and toughness over other weaker materials.

- Normally run between stop collars for applications that require rotating casing.

- Ribs are welded to the end collar to provide maximum strength with a generous weld radius and smooth transition to the main rib body that also has an axial radius.

- Typical friction factor is .12-.14 for open-hole. The rib’s smooth OD will not plow in deviated wellbores.

- Spiral Rib shape creates turbulence to optimize mud removal and prevent cement channeling. Straight Rib is also available.

- Hollow Rib shape will deform at higher side forces, typically 30-40,000 lbs, so casing can still be run to total depth even if wellbore restrictions or unstable formations are encountered.

- Hollow-Vane Centralizers are symmetrical, so drag into or out of the wellbore will be similar.

Disrupter®

The Disrupter is a unique composite solid body slip-on spiral blade centralizer. Featuring an advanced design that allows the casing to oscillate in the wellbore, the Disrupter® reduces friction and provides less drag, allowing the casing to easily glide through wellbore deviations and horizontal sections. The Disrupter exploits the negative energy of hole drag, by turning side contact force into applied casing oscillation.

The Disrupter has successfully been run in wells with bottom hole temperatures surpassing 390°F in geothermal applications. Featuring a solid body design made up of a high-grade resin, the Disrupter is able to withstand the typical impact, wear, and heat resistance encountered downhole.

Powered by a Patented Design

- Takes the path of least resistance

- Navigates wellbore obstructions

- Accommodates high DLS and whipstock applications

Benefits

- Independent from all formations, completion types, and mud types

- Reduces open hole friction factors by 20+%

- Delivers increased available hook load at total depth by 25+%

- Faster run times and increased trip speed by 15+%

FET Davis-Lynch is an authorized provider to sell the DISRUPTER® Centralizer, designed and manufactured by Friction Tool Solutions based in Alberta, Canada.

FET Davis-Lynch is an authorized provider to sell the DISRUPTER® Centralizer, designed and manufactured by Friction Tool Solutions based in Alberta, Canada.

Welded Solid Body Centralizer

Solid-body Welded Centralizers have ribs that are welded to a continuous steel sleeve. The ribs, or blades, may be straight or angled (spiral-vane) to provide flow diversion. Ribs provide sufficient contact with the wellbore to provide centralization but prevent wall sticking. They can be installed stationary to the casing (set screws) or free to rotate. Length of movement is determined by placement of stop devices or length of casing joints.

- Maintain centralization through positive stand-off.

- Provide rugged centralization that is less likely to be damaged when running in the hole.

- Reduce torque required to rotate the casing.

- Straight-vane reduces the drag forces when running casing.

- Low coefficient of friction.

- Spiral-vane provides flow diversion which improves mud

Bow Spring

Hinged Non-Weld Bow Spring Centralizer

Davis-Lynch™ Non-Weld Type “NW” centralizers are designed to exceed the performance requirements of API Specification 10D for both starting and restoring forces.

The Non-Welded Turbolizer is a centralizer with metal fins installed on the bows to help induce turbulence in the cement slurry during pumping operations. Like the spring bows, the fins are made of heat-treated alloy steel. This makes them flexible, which minimizes damage while moving downhole. The Davis-Lynch Turbolizer incorporates the same nonwelded end collar to springbow interlocking adjoinment as the Davis-Lynch centralizer. Turbolizers are available in the same sizes and bow heights as centralizers. As with the Davis-Lynch centralizer, turbolizers can be manufactured with a builtin stop device. These items are available on special order.

Other design features of the Type “NW” Centralizer include:

- Bow springs made of alloy steel which are heat treated and tempered to a hardness of 42-44 Rc ensures proper and consistent spring characteristics.

- End collar hinges that are folded to the inside. This minimizes the collar stretch that tends to occur when centralizers encounter tapers common to some pipe connections.

- A reinforcing rib stamped into the end collar. This strengthens it to ensure maintenance of its round configuration during transport.

- Several different spring bow heights that are available to accommodate most any casing-to-hole configuration.

- Centralizers with built-in stop devices as well as those for unusual sizes available on request.

Hinged Non-Weld Semi-Rigid Centralizer

The Semi-Rigid Centralizer features a unique bow design that allows each centralizer two contact points with the borehole while having low starting and running forces, but very high restoring or centering forces. It is also a non-weld variety and features a bow with dual curves giving the bow an “S” shape. It simultaneously provides features found desirable in both bow-spring and rigid centralizers. Davis-Lynch Semi-Rigid Type “SR” centralizers are designed to exceed the performance requirements of API Specification 10D for both starting and restoring forces.

- As the bow OD is typically very close to hole size, the centralizer has very low starting and drag forces.

- The double profile of the bow results in much higher restoring forces than conventional bow-springs.

- Bows are made from alloy steel, heat-treated and tempered.

- Utilizes Davis-Lynch patented interlocking bow attachment to end collars.

- Can be run in highly-deviated and horizontal wellbores.

- Can be run over casing connections or stop collars.

- Can be supplied with built-in stop device if requested.

- Bows still provide some flex that allow the centralizer to compress through tight spots and severe doglegs unlike a conventional rigid centralizer.

- Can be provided with turbolizer fins to help induce turbulence in the cement slurry during pumping operations.

Hinged Non-Weld Rigid Centralizer

This Forum product features the patented interlocking adjoinment between the end collars and bow springs that is widely used though out Davis-Lynch™ centralizers due to its effectiveness.

Coupling this feature with stamped sheet steel or stamped and welded bow springs results in a low drag, rigid unit that is sought after by today’s operators.

Not only does the Rigid bow centralizer deliver low drag, it also delivers optimum concentricity for cementing operations, and it can be used in cased hole as well as open hole applications with the same results.

These centralizers are offered in a wide assortment of bow sizes to accommodate most casing-to-hole configurations. They can also be configured using a new type of bow that is stamped and does not require welding to become rigid. These bows are fixed to the end collar in the same patented non-welded fashion.

One Piece Bow Spring Centralizer

The Forum One Piece Bow Spring Centralizer is nonweld uni-body bow-type centralizer. These Centralizers are made from a single piece of alloy steel tube that is precision-cut with a laser to form the end collars and bow springs as one unitary body. The bows are then expanded to the desired outside diameter with advanced tooling. Finally, the entire unit is heat treated to maximize the restoring force of the bows as well as provide strength to the whole unit. Optionally it can be coated with various coatings to provide friction reduction, corrosion prevention or protection for hanger seal areas.

- The strongest bow-type centralizer available today.

- Manufactured from tubular steel with closer tolerances that allow for running in tighter annular spaces (close-tolerance wellbores).

- More stand-off than solid-body centralizers in conventional and bi-center wellbores (where the open-hole ID drilled below a casing string is larger than the casing ID).

- As the bow OD is typically the same or only slightly larger than the wellbore ID, drag forces are considerably lower than conventional bow-type centralizers, yet restoring forces are higher.

- Greater flow-by area than most bow-type or solidbody centralizers.

- Easily coated with low-friction polymers to reduce friction factor in extending reach horizontal casing installations, or to prevent erosion due to plating of expensive casing alloys when installed in a corrosive environment. Also coatings can prevent damage to sensitive areas such as hanger seal ID’s, etc.

- Radially curved bows decrease friction and reduce the chance of drag or damage when passing through milled-casing windows.

- Set screws can be integrated into the lower end collar to provide anchoring without the need for a separate stop collar.

Slip On Close Tolerance Rotating Centralizer

Similar to our Slip-on Close-Tolerance Bow Spring Centralizer, however, this version has a fast-rising bow spring to allow running a set-screw stop collar inside the centralizer.

- Set-screw stop collar is run internally so that the centralizer may be pulled into and out of the wellbore for lower starting/drag forces.

- Allows rotation of the casing.

- Can be optionally run between stop collars.

- Bows are welded flush with end collar to provide maximum strength with minimum clearance.

- Bows are made of alloy steel and are heat-treated and tempered to a hardness that ensures proper and consistent spring characteristics.

Slip on Close tolerance Welded Bow Spring Centralizer

In applications for running casing in close-tolerance wellbores or slim holes, Forum offers a special bow spring centralizer for these requirements. To provide optimum performance in close-tolerance wellbores, these centralizers feature low starting forces and high restoring forces. These centralizers consist of a solid type end collar for slipping over the pin end of the casing joint.

- Available with set screws in the lower end collar for an integrated stop device (standard), so that no separate stop collar is necessary. The end collar with set screws should be run down (toward the bottom of the hole) so that the centralizer is pulled into the wellbore to optimize starting/drag forces.

- Can be optionally run between stop collars for applications that require rotating casing.

- Bows are welded flush with end collar to provide maximum strength with minimum clearance.

- Bows are made of alloy steel and are heat-treated and tempered to a hardness of 42-44 Rc ensuring proper and consistent spring characteristics.

- Typical applications include 5” casing in 6” hole, 7-5/8” casing in 8-1/2” hole, and 9-5/8” casing inside 10-5/8” hole.

- Recommended set screw torque is 20-25 ft-lbs.

Stop Devices

Forum manufactures accessory items known as Stop Collars. Stop Collars provide a means of restricting the movement of a centralizer on the joint of casing, when the centralizer is not installed over a casing coupling. One type, known as a Friction Stop Collar (sometimes called a Bolt-Type Stop Collar), is attached to the casing by tightening a bolt that causes the band of steel to grip the casing. The second type is known as a Set-Screw Stop Collar, which slips on the casing and is attached by tightening set screws that grip the outside diameter. Set-Screw Stop Collars are also available with dual-rows of set-screws for extra holding power, known has “Heavy-duty”. Set-Screw Stop Collars are also available in a hinged type.

Hinged Friction Stop Collar

Hinged Set-Screw Stop Collar

Heavy-Duty Set-Screw Stop Collar

Set-Screw Stop Collar

Centralizer Sub

As a leading OEM for downhole casing equipment, Davis-Lynch is proud to manufacture Centralizer Subs for cementing challenges posed during lean profile drilling operations. Custom engineered to match or exceed the material grade and thread performance installed, Davis-Lynch Centralizer Subs’ proven technology allows the unit to contract and expand as needed for the well bore situation. Run as an integral part of the casing string, our Centralizer Subs are offered in bow-spring and rigid versions and available in almost any casing size, grade, or thread and for use in the most challenging wellbore configurations.

Designed to match the drift requirements on the connections being used, the Davis-Lynch Centralizer Sub is a tight-tolerance stack centralizer with special tested performance features that can collapse almost virtually flat, yet still respond back to a bow spring shape and provide sufficient restoring force in the open hole section.

Design

- The Centralizer Sub becomes an integral part of the casing string.

- Sub designs can match most Casing Grade Materials and Casing Threads.

- Centralizer Designs can be of Bow Spring or Solid Vane type.

- Exceptional quality built with full traceability of component materials starting from the mill material certificates to well site delivery.

Centralizer Sub Specifications

| Casing Size | Bow ID (in) | Rigid OD (in) |

| 7 | 8.5 | 7.25 |

| 9 5/8 | 12.25 | 10.25 |

| 9 7/8 | 12.25 | 10.25 |

| 11.75 | 14.75 | 12 |

| 13 5/8 | 17.5 | 13.93 |

| 14 | 17.5 | 14.5 |

| 16 | 20 | 16.4 |

| 18 | 22 | 18.4 |

Benefits

- Used in close tolerance and under-reamed wellbore applications

- Suited for use in horizontal, tortuous well paths, and passing through tight restrictions.

- Can pass safely through tight clearance Sub- Sea equipment such as Well Heads, Connectors, and Landing Seats.